How to Choose Between 110V, 240V, and 415V Extension Leads

Choosing the right extension lead isn’t just about length or plug type it’s about safety, performance, and compliance with regulations. Whether you’re on a construction site, working in an industrial facility, or simply setting up tools at home, selecting the correct voltage extension lead can prevent accidents, protect equipment, and ensure efficient power usage. But with so many options 110V, 240V, and 415V extension leads how do you know which one is right for you?

This guide breaks down the key differences, best use cases, and safety considerations so you can make the right choice every time.

What is 110V, 240V, and 415V Power Supply?

Before diving into extension leads, it’s important to understand what these voltages mean:

- 110V Power Supply

- Commonly used in construction and outdoor sites in the UK.

- Offers reduced voltage to minimize the risk of electric shock in wet or hazardous environments.

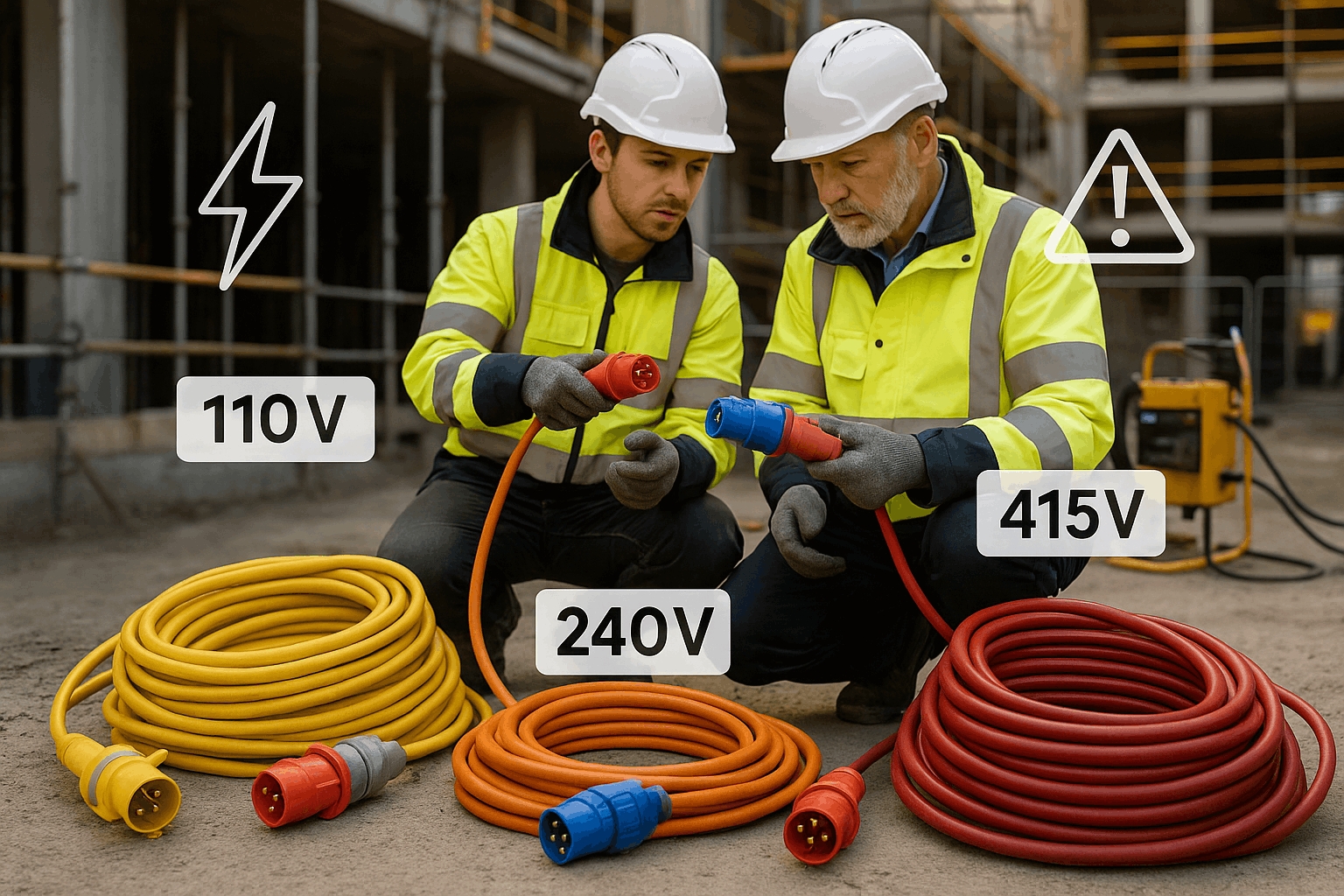

- Yellow connectors and cables are the standard for site extension leads.

- 240V Power Supply

- Standard domestic and office voltage in the UK.

- Used for everyday appliances, power tools, and office equipment.

- Blue connectors and extension leads are typically used for this voltage.

- 415V Power Supply

- Known as three-phase power, commonly used in industrial and heavy-duty environments.

- Powers machinery, large motors, and high-demand equipment.

- Red connectors are standard for 415V industrial extension leads.

Key Differences in Safety, Usage, and Compliance

- Safety Standards

- 110V extension leads are required on construction sites for worker safety.

- 240V leads are safe for homes and offices but not recommended for hazardous sites.

- 415V leads must meet strict compliance standards and are generally handled by trained professionals.

- Usage

- 110V: Portable tools, lighting, and site equipment.

- 240V: Household appliances, office gear, and light-duty machinery.

- 415V: Industrial machinery, compressors, and heavy plant equipment.

- Compliance

- Health and safety regulations often mandate 110V on UK construction sites.

- 240V and 415V extension leads should be properly rated, tested, and inspected to comply with workplace regulations.

Best Use Cases

- 110V Extension Lead

- Best for: Construction sites, outdoor work, temporary site power setups.

- Example: Powering drills, grinders, or lighting towers safely on-site.

- 240V Extension Lead

- Best for: Domestic, office, and light commercial use.

- Example: Running computers, printers, kitchen appliances, or small workshop tools.

- 415V Extension Lead

- Best for: Factories, workshops, and heavy industry.

- Example: Supplying power to welding machines, conveyors, or industrial motors.

How to Select the Right Extension Lead

When choosing between 110V, 240V, and 415V extension leads, consider the following:

- Environment

- Wet, outdoor, or hazardous = 110V.

- Home or office = 240V.

- Heavy industrial = 415V.

- Tool or Equipment Voltage

- Always match the extension lead to the tool’s rated voltage.

- Compliance & Safety

- Follow HSE guidelines for site use.

- Ensure the extension lead is certified and tested for its intended voltage.

- Length & Load Capacity

- Longer cables can cause voltage drop choose a safe extension cable with adequate rating.

Common Mistakes to Avoid

- Using 240V leads on construction sites where 110V is mandatory.

- Overloading extension leads with multiple high-power devices

- Ignoring IP ratings leads for outdoor use should be waterproof and dustproof.

- Mixing connectors and voltages always use the correct color-coded plugs (yellow = 110V, blue = 240V, red = 415V).

FAQs

1. What is the difference between 110V and 240V extension leads?

Answer:

A 110V extension lead is mainly used on construction sites for safety in hazardous conditions, while a 240V extension lead is standard for domestic and office use.

2. Why do construction sites use 110V extension leads?

Answer:

UK health and safety regulations require 110V extension leads on construction sites to reduce the risk of electric shock, especially in wet or outdoor environments.

3. What is a 415V extension lead used for?

Answer:

A 415V extension lead is designed for industrial use, powering heavy-duty machinery such as motors, compressors, and welding equipment that need three-phase power.

4. Can I use a 240V extension lead instead of a 110V on site?

Answer:

No. Construction sites legally require 110V site extension leads for worker safety. Using a 240V lead in these environments can be dangerous and non-compliant.

5. How do I choose the right extension lead?

Answer:

Match the lead to the tool’s rated voltage (110V, 240V, or 415V), consider the environment (site, home, or industry), and ensure it meets safety standards and load capacity.