Latest Weekly News

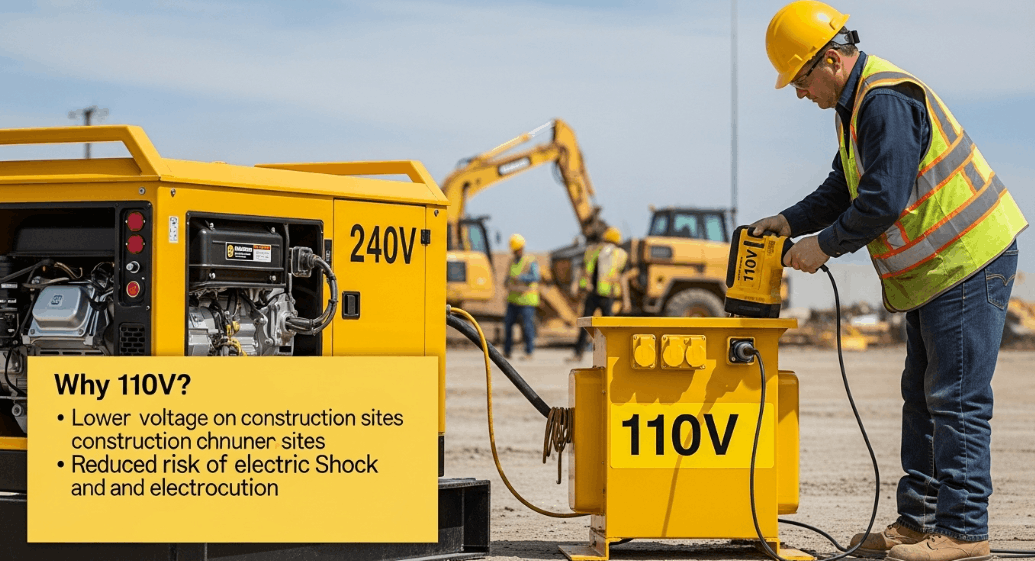

Why Construction Sites Use 110V: Safety, Standards & Smarter Power

Construction sites often use 110 V (instead of standard household 230 V) for portable tools and temporary power, because it provides a safer, regulated supply, reducing electrical hazards in risky site environments.

Main Reasons for Using 110 V

Typical Site Voltage Usage

- 110 V – the standard/recommended voltage for portable tools, lighting, and temporary equipment.

- 400 V (3-Phase) – used for heavy machinery (mixers, hoists, cranes).

- 230 V – only used in limited, controlled, dry indoor areas; generally discouraged for standard site work.

What Is a “110V Site Transformer” & Why It Matters

- A “110 V site transformer” steps down standard mains supply (e.g. 230 V) to 110 V. This ensures tools and lighting operate at the safer, lower voltage.

- Many site tools, extension leads, cable reels, and lighting systems are built specifically for this 110 V supply.

Why This Is Important

- Construction sites are inherently hazardous: water, dust, rough handling, exposed cables, foot-traffic, temporary setups. 230 V is considered too dangerous in such unstable conditions.

- Using 110 V (via a centre-tapped earth transformer) dramatically reduces the severity of electric shock: contact with a live conductor would typically expose a worker to ~55 V to earth (instead of 230 V), which is far less likely to cause fatality.

- Because of this reduced risk, many international contractors, safety regulators (e.g. via standards like Health & Safety Executive (HSE) in UK) and insurers favor or mandate 110 V systems on sites.

A Real-World Problem: What Can Still Go Wrong

Problem: Even with 110 V systems, misuse or improper maintenance can lead to incidents – e.g., damaged cables, faulty transformers, overloaded circuits, or neglecting periodic safety checks. This reduces the benefit of lower voltage and may still cause shocks or fire hazards.

Common problems include:

- Damaged or worn 110 V cables/extension leads (cuts, abrasions, water ingress)

- Use of non-site-rated extension leads or domestic plugs rather than proper site-grade cables

- Overloading circuits with heavy tools, causing overheating or voltage drop

- Lack of regular inspection or PAT (Portable Appliance Testing) / visual checks

Such problems can undermine the safety advantages of 110 V and expose workers to risk.

Solution & Best Practices

“How to use 110V safeky on construction sites?” Below are the best practices for safe use.

- Use proper 110 V site-rated equipment: Transformers, cable reels, extension leads, plugs/sockets – all should be industrial / site-rated, not domestic.

- Ensure adequate insulation and environmental protection: Choose cables with the correct IP rating (e.g. IP44 or higher) for dust/water resistance if using outdoors.

- Perform regular inspections and testing: Before each use – a visual check of cables, plugs, transformers. For portable tools, conduct formal PAT testing periodically (e.g. every 3 months for active site equipment).

- Avoid overloading circuits and minimize long cable runs: Use adequately rated cables (proper cross-section), avoid daisy-chaining multiple long leads, and ensure load capacity matches tool requirements.

- Segregate power for different usages: Use 110 V for portable tools/lighting; reserve higher voltages (e.g. 400 V 3-phase) only for heavy machinery that demands it, in compliance with safety regulations.

FAQs

- Why do construction sites use 110 V instead of 230/240 V?

Because 110 V greatly reduces shock and fatality risk in hazardous site conditions while still powering tools safely.

2. Does using 110 V make tools less effective?

No – most site tools are built for 110 V and work effectively; only heavy machinery typically needs higher voltages.

3. Is 110 V mandatory on construction sites?

In many regions (especially the UK), 110 V is strongly recommended or required for portable equipment to meet safety standards and insurance rules.