How to Choose the Right 110V Cable Reels for Heavy-Duty Industrial Use

110V cable reels are the recognised standard for temporary power on UK construction and industrial sites. By lowering voltage compared to 230V, the risk of serious electric shock is significantly reduced.

A professionally manufactured 110v cable drum supports:

- Safer power distribution

- Consistent voltage delivery

- Compliance with site regulations

- Long-term durability in demanding environments

Connexion Electrical designs industrial-grade 110 volt cable reels specifically for these applications.

Choosing the Correct Cable Length

Selecting the correct cable length is critical for efficiency, safety, and performance. The goal is to reach equipment comfortably without excess cable on the ground.

Key considerations include:

- Size of the work area

- Distance from the transformer or power source

- Number of tools in operation

Shorter cable reels are ideal for confined areas. For example, compact workspaces and indoor zones benefit from shorter runs where cable control and mobility matter most.

Using an unnecessarily long 110 volt extension reel can increase voltage drop and create avoidable trip hazards, making correct length selection a key safety decision.

Cable Thickness and Load Capacity

Cable thickness determines how much electrical load the reel can safely handle.

- 1.5mm² cable – Suitable for light tools and intermittent use

- 2.5mm² cable – Required for heavy-duty equipment and continuous operation

For higher-load tools, thicker cables reduce resistance, limit heat build-up, and maintain consistent power delivery. This makes heavier-gauge 110v cable 50m configurations far more suitable for industrial environments.

16A Rating: The Industry Benchmark

A 16amp extension reel is the standard rating for professional 110V systems. It ensures compatibility with site transformers and supports high-demand tools such as mixers, lighting towers, and power saws.

All industrial 110V cable reels should meet this rating to prevent overheating and ensure safe operation.

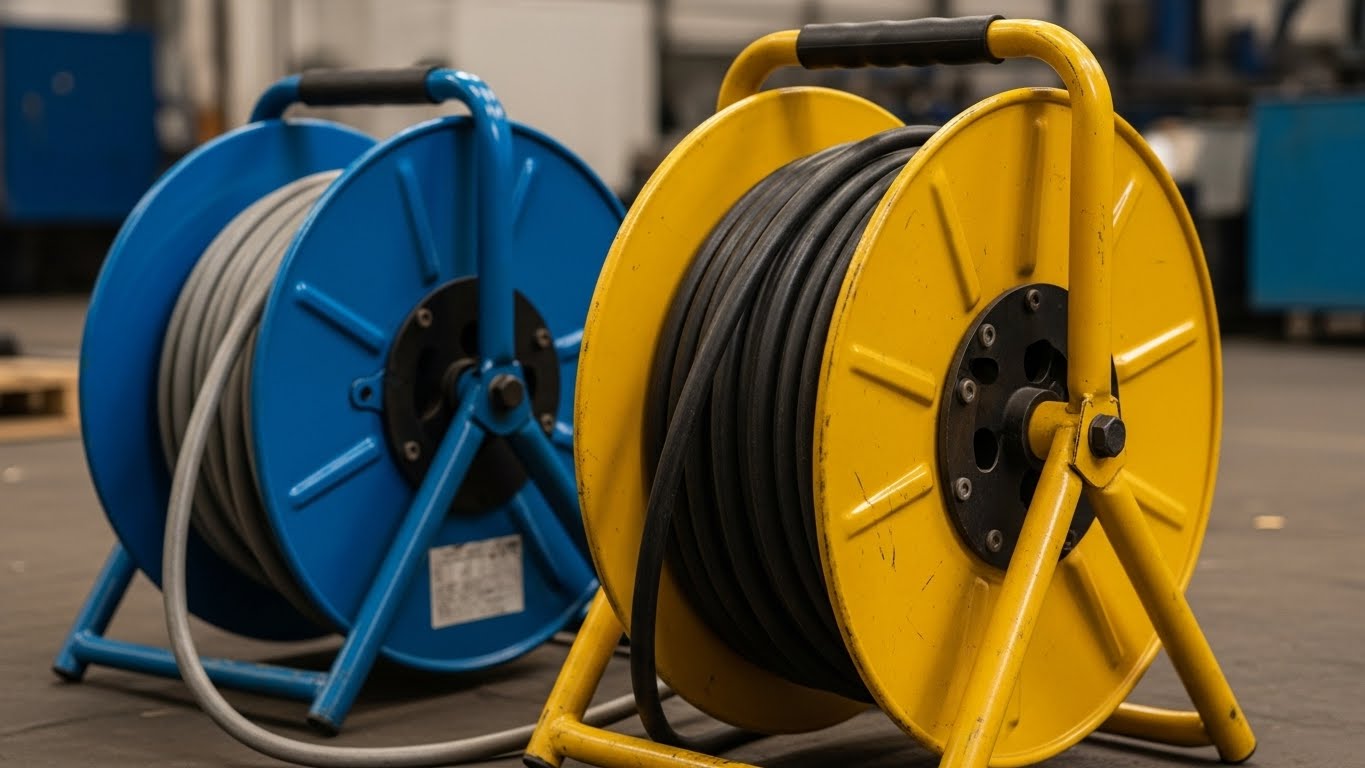

Durability and Build Quality (Industrial Comparison)

Durability is essential in harsh site conditions where reels are exposed to impact, dust, moisture, and frequent handling.

| Product Configuration | Drum Material & Strength | Cable Protection | Suitable Site Environment |

| 110V Cable Reel 25m 1.5mm | Impact-resistant heavy-duty drum | High-visibility insulated PVC | Small to medium indoor sites |

| 110V Cable Reel 50m 2.5mm | Reinforced industrial-grade drum | Thick abrasion-resistant jacket | Medium to large construction sites |

| 110V Cable Drum 100m 2.5mm | Extra-rugged reinforced drum design | Maximum mechanical and wear protection | Large industrial and infrastructure sites |

Safety Features That Matter

Maintaining construction site electrical safety goes beyond reduced voltage. A high-quality 110V cable reel should include:

- Thermal overload protection

- Clear voltage and amperage identification

- Secure socket housings

- Stable drum frames to prevent tipping

Longer cable drums should always be fully unwound during use to avoid heat build-up and cable damage.

Common Mistakes to Avoid

- Using thin cable for high-load tools

- Selecting domestic reels instead of industrial-rated 110v cable drums

- Leaving reels partially wound under load

- Ignoring 16A current requirements

FAQs

Why is 110V safer for construction sites?

Lower voltage significantly reduces the severity of electric shock, making 110V safer for temporary power.

Is a 16amp extension reel suitable for heavy-duty tools?

Yes. A 16amp extension reel with 2.5mm² cable supports most construction and industrial equipment.

Which cable reel is best for large sites?

Long-range projects benefit from extended-length 110v cable drums designed for durability and high load capacity.

Should cable reels always be fully unwound?

Yes. Fully unwinding improves heat dissipation and prolongs cable life.