Construction Site Electrical Equipment Essentials: A Complete Safety Guide for UK Builders

Power failures and electrical hazards are among the top causes of construction delays in the UK. Without proper electrical equipment, sites face safety risks, regulatory penalties, and costly downtime. In this guide, we’ll cover everything you need to know about essential electrical equipment that keeps construction sites safe, compliant, and productive.

Why Electrical Equipment Is Critical on Construction Sites

Construction sites are inherently dangerous environments. Heavy machinery, exposed wiring, wet conditions, and constant movement create the perfect storm for electrical accidents. The Health and Safety Executive reports that electrical incidents on construction sites result in serious injuries and fatalities every year.

Proper electrical equipment isn’t just about keeping the lights on. It’s about protecting workers, meeting legal obligations, and ensuring projects stay on schedule. A single electrical failure can halt work for hours or days, costing thousands in lost productivity.

UK construction sites must comply with BS 7671 wiring regulations, CDM regulations, and HSE guidelines. Non-compliance can result in hefty fines, project shutdowns, and criminal prosecution in severe cases. The right electrical equipment forms the foundation of a safe, compliant worksite.

Sites without adequate electrical infrastructure face constant problems. Tools won’t run efficiently, lighting is inadequate, and workers improvise dangerous solutions. Investing in proper electrical equipment from day one prevents these issues and creates a professional work environment.

What Counts as Essential Construction Site Electrical Equipment?

Construction site electrical equipment encompasses everything needed to distribute power safely across temporary work environments. These essentials differ significantly from standard commercial or domestic electrical systems.

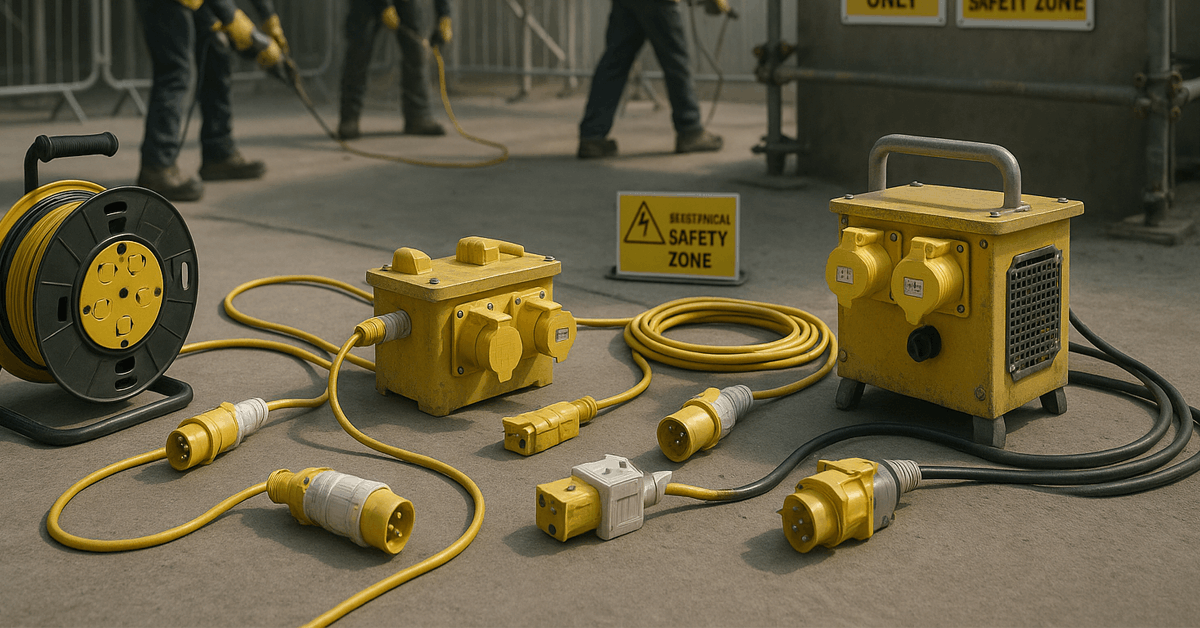

Power Distribution Units and Boards: These are the heart of site electrical systems. Distribution boards with RCDs and MCBs protect circuits and enable safe power distribution. Portable distribution units allow flexible positioning as work progresses across different site areas.

Industrial Socket Outlets: Heavy-duty sockets rated for construction use, typically 16A, 32A, and 63A configurations. Commando-style sockets with IP44 or higher ratings withstand weather and rough handling. Color-coded systems prevent incorrect voltage connections.

Cable Reels and Extension Leads Systems: Professional-grade cable reels with thermal cutouts prevent overheating. Arctic-grade flexible cables remain pliable in cold weather. Proper cable management reduces trip hazards and cable damage from site vehicles.

Site Lighting: Adequate illumination is both a safety requirement and productivity booster. LED festoon lighting, tower lights, and portable work lights ensure visibility during early mornings, evenings, and winter months. Emergency lighting provides safety during power failures.

Transformer Units: Step-down transformers convert 400V three-phase to 230V single-phase or provide 110V center-tapped earth systems. The 110V system is the UK construction standard, offering enhanced safety through reduced voltage.

Temporary Electrical Installation Systems: Quick-deployment systems including spider boxes, splitter units, and plug-in distribution boxes. These enable rapid setup and reconfiguration as construction phases progress.

Testing and Safety Equipment: Voltage testers, socket testers, RCD testers, and multimeters ensure electrical systems function correctly. Lockout/tagout devices enable safe isolation during maintenance work.

Top Benefits of Using Proper Electrical Equipment

Worker Safety and Risk Reduction

Quality construction site electrical equipment incorporates multiple safety features. RCDs trip within milliseconds if earth faults occur, preventing electrocution. Overload protection prevents cable overheating and fire risks. IP-rated enclosures protect against water ingress, critical in Britain’s wet climate.

Proper equipment also includes clear labeling, color coding, and intuitive designs that reduce user error. When workers can quickly identify voltage levels and connection types, dangerous mistakes become far less likely.

Full Regulatory Compliance

Using approved electrical equipment ensures compliance with BS 7671, BS 7909, and HSE construction site regulations. Equipment should carry proper CE/UKCA marking and meet British Standards requirements. Compliance protects you during inspections and demonstrates duty of care to your workforce.

Regular testing and certification of electrical equipment also forms part of your legal obligations. Proper equipment comes with documentation that proves compliance and facilitates required periodic testing.

Improved Productivity and Uptime

Reliable electrical equipment means fewer breakdowns and delays. When power distribution works flawlessly, tradespeople focus on their core work rather than troubleshooting electrical problems. Tools run at optimal performance, lighting ensures work quality, and heating keeps workers comfortable in cold conditions.

Quick-deployment systems also speed up site setup. Modern plug-and-play distribution equipment can be operational in minutes, getting projects started faster.

Weather Resistance and Durability

UK construction sites endure rain, wind, frost, and mud. Industrial electrical equipment designed for construction use features weatherproof housings, sealed connections, and corrosion-resistant materials. IP44 minimum rating ensures protection against splashing water from any direction.

Arctic-grade cables remain flexible even in freezing temperatures, while robust construction withstands being walked on, dropped, or exposed to debris. This durability translates to longer equipment life and lower replacement costs.

Cost Efficiency and Value

While construction-grade electrical equipment costs more initially, it delivers superior value over time. Equipment lasts years rather than months, reducing replacement frequency. Fewer failures mean less downtime and lower labor costs for repairs.

Energy-efficient LED lighting and modern distribution systems also reduce electricity consumption. Over a long project, these savings can be substantial.

Temporary vs. Permanent Electrical Installations

Understanding the difference between temporary and permanent installations is crucial for construction site planning.

Temporary Construction Installations: These systems power the construction process itself. They’re designed for portability, rapid deployment, and harsh conditions. Temporary installations include distribution boards on stands, cable reels, portable lighting, and plug-in equipment.

Temporary systems prioritize flexibility and safety over aesthetics. Equipment can be repositioned as work progresses. The 110V system commonly used in UK temporary installations provides enhanced safety through reduced shock risk.

Regulations for temporary installations appear in BS 7671 Section 110 and BS 7909. These standards address unique construction site challenges including outdoor exposure, mechanical damage risk, and untrained person access.

Permanent Building Installations: As construction progresses, permanent electrical systems are installed within the structure. These follow standard BS 7671 regulations and form the building’s final electrical infrastructure.

The transition from temporary to permanent power is a critical phase. Often, both systems run simultaneously while permanent installations are tested and commissioned. Clear separation and proper labeling prevent confusion and cross-connection errors.

Key Differences: Temporary installations use more robust, portable equipment with higher IP ratings. They prioritize quick setup and reconfiguration. Permanent installations focus on aesthetics, efficiency, and integration with building systems.

Construction site managers must maintain temporary systems throughout the build, conducting regular inspections and testing. As areas complete, temporary power is withdrawn and permanent systems activated.

Step-by-Step Guide to Setting Up Site Electrics

Setting up construction site electrical systems requires careful planning and execution.

Step 1: Conduct Site Power Assessment

Survey the site and list all equipment that will require power. Include tools, lighting, heating, welfare facilities, and site offices. Calculate total power requirements with a 30% safety margin. Determine whether single-phase or three-phase supply is necessary.

Step 2: Design Distribution Layout

Plan where distribution boards will be positioned to minimize cable runs. Consider site logistics, keep boards away from excavation zones and vehicle routes. Ensure boards are accessible but protected from damage.

Step 3: Arrange Utility Connection

Contact the Distribution Network Operator to arrange temporary supply. This process can take weeks, so start early. Specify required capacity and connection point. Confirm whether you need single or three-phase supply.

Step 4: Install Main Distribution Board

Position the primary distribution board near the utility connection point. Mount on a stable surface or dedicated stand. The board should include main isolator, RCDs, MCBs, and appropriate socket outlets. All metalwork must be properly earthed.

Step 5: Deploy Secondary Distribution

Run armored cables or protected flexible cables to secondary distribution points across the site. Use cable protectors where cables cross walkways or vehicle routes. Position spider boxes and distribution units in work areas.

Step 6: Set Up Lighting Systems

Install festoon lighting along main routes and work areas. Position tower lights in large open areas. Ensure adequate illumination meets HSE minimum standards. Include emergency lighting where required.

Step 7: Test and Certify

Conduct thorough testing of all circuits using appropriate equipment. Verify RCD operation, earth continuity, insulation resistance, and polarity. Document all test results. Issue electrical installation certificates as required.

Step 8: Implement Inspection Schedule

Establish regular inspection and testing routines. Visual inspections should occur daily. Formal testing intervals depend on equipment type and usage conditions—typically monthly for harsh environments.

Case Studies: UK Construction Site Success Stories

London High-Rise Development: A major residential tower project in East London implemented a comprehensive 110V distribution system from day one. By investing in quality electrical infrastructure, the developer eliminated electrical delays entirely. The project completed two weeks ahead of schedule, with the electrical investment paying for itself through avoided downtime costs.

Manchester Commercial Retrofit: A historic building conversion project faced challenges powering tools while protecting heritage features. The contractor used flexible cable reel systems and portable distribution units that could be repositioned weekly. This adaptability enabled work to progress without permanent installations damaging historic fabric during construction.

Edinburgh Housing Estate: A 200-home development implemented LED festoon lighting throughout the site, reducing electricity costs by 60% compared to halogen alternatives. The improved illumination also reduced accidents during winter months when daylight hours were limited.

Birmingham Infrastructure Project: A major roads project used weatherproof IP65-rated distribution equipment during a particularly wet winter. While other contractors struggled with water damage to electrical systems, this project maintained full power availability throughout, keeping the program on track.

Cardiff Stadium Expansion: Event-style temporary power systems proved ideal for stadium construction with multiple contractors. The spider box distribution system allowed each trade dedicated circuits while enabling rapid reconfiguration as work zones changed.

Frequently Asked Questions

Q. Why is 110V preferred on UK construction sites?

The 110V center-tapped earth system reduces shock risk significantly compared to 230V. If someone contacts a live conductor, the maximum voltage to earth is only 55V, which is generally considered safe. This reduced voltage is mandated for hand-held tools and portable equipment on most UK construction sites.

Q. How often should construction site electrical equipment be tested?

Visual inspections should occur before each use for hand-held equipment. Formal PAT testing intervals depend on use conditions, typically every 3 months for construction equipment. Fixed installations require periodic inspection and testing, usually every 3 months for construction sites per BS 7671 recommendations.

Q. What IP rating is required for construction site equipment?

Minimum IP44 rating is standard for outdoor construction site electrical equipment. This provides protection against solid objects over 1mm and water splashing from any direction. For particularly exposed locations or equipment that may be submerged, IP65 or IP67 ratings are advisable.

Q. Can I run site electrics myself or do I need a qualified electrician?

All electrical installation work must be performed by competent persons. For construction sites, this typically means qualified electricians with construction experience. DIY electrical work on construction sites violates HSE requirements and creates serious liability issues.

Q. What size generator do I need if mains power isn’t available?

Calculate total power requirements of all equipment that might run simultaneously, then add 30-40% capacity margin. A typical small construction site requires 20-45kVA. Larger sites may need 100kVA or multiple generators. Always specify diesel generators for construction use.

Q. Do I need RCD protection on all construction site circuits?

Yes. BS 7671 requires 30mA RCD protection for socket outlets rated up to 32A and for mobile equipment rated up to 32A used outdoors. This protection is non-negotiable on construction sites due to the high risk environment.

How do I protect cables on a busy construction site?

Use armored cables for permanent runs. Protect flexible cables with heavy-duty cable protectors or ramps where they cross vehicle routes or walkways. Route cables overhead where possible. Mark cable routes clearly and brief all site personnel on their locations.

Conclusion

Essential construction site electrical equipment forms the backbone of safe, efficient building projects. From distribution boards and socket outlets to lighting systems and testing equipment, each component plays a vital role in protecting workers and maintaining productivity.

Key takeaways include prioritizing safety through proper equipment selection, ensuring full compliance with UK regulations, implementing robust distribution systems, and maintaining equipment through regular testing and inspection.

Never compromise on electrical equipment quality. The initial investment in proper construction-grade electrical supplies pays dividends through enhanced safety, reduced downtime, regulatory compliance, and long-term durability.Ready to equip your construction site properly? Contact our team today for expert guidance on electrical equipment tailored to your project requirements. Request a quote and start your next build with confidence, safety, and compliance guaranteed.