Energy Efficiency Tips for 110V Transformers in Industrial Settings

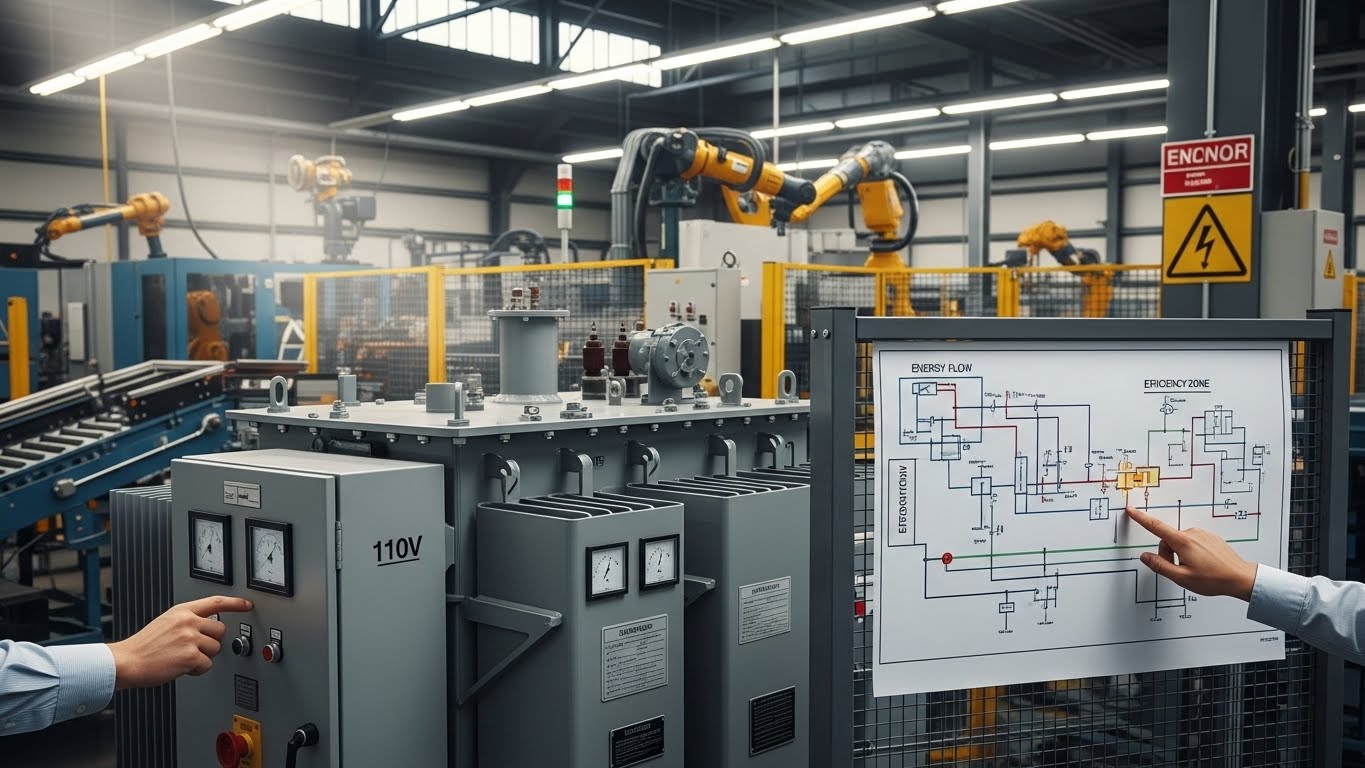

In industrial and construction environments, 110V site transformers play a critical role in powering tools, lighting, and temporary infrastructure. While safety is the primary reason for using a 110 volt site transformer, energy efficiency is becoming increasingly important due to rising electricity costs, sustainability targets, and stricter regulations.

This guide explains how to reduce transformer energy losses, improve operational efficiency, and choose energy saving transformers that deliver both safety and performance.

What Is a 110V Site Transformer?

A 110V site transformer is a step-down isolation transformer that converts higher supply voltages (typically 230V or 400V) to 110V. These transformers are widely used in:

- Construction sites

- Industrial maintenance projects

- Temporary site electrics

- Outdoor or high-risk working environments

Their centre-tapped design (55-0-55V) significantly reduces the risk of electric shock, making them a safety standard in many regions.

Understanding Transformer Energy Losses

To improve efficiency, it’s essential to understand where energy is lost.

Main Types of Transformer Energy Losses

- Core (Iron) Losses

- Occur whenever the transformer is energised

- Caused by hysteresis and eddy currents

- Occur whenever the transformer is energised

- Copper (Winding) Losses

- Increase with load

- Caused by resistance in the windings

- Increase with load

- Idle Losses

- Result from leaving transformers powered when not in use

- Result from leaving transformers powered when not in use

Reducing these losses is the foundation of energy efficient transformers.

Energy Efficiency Tips for 110V Transformers

1. Choose Energy Efficient Transformers

Modern energy saving transformers use:

- High-grade silicon steel or amorphous cores

- Improved winding geometry

- Advanced insulation materials

These features significantly reduce no-load and load losses compared to older models.

2. Use Low Loss Transformers for Continuous Operation

If your transformer operates for long periods, low loss transformers are essential. They:

- Consume less energy at idle

- Generate less heat

- Offer longer service life

This is particularly important in industrial settings where temporary site electrics may remain energised 24/7.

3. Right-Size the Transformer Capacity

Oversized transformers waste energy through unnecessary core losses, while undersized units suffer from higher copper losses.

Best practice:

- Match transformer rating closely to actual load demand

- Allow reasonable headroom (typically 20–25%)

This balance optimises efficiency and reliability.

4. Reduce Idle and Standby Time

One of the simplest energy-saving strategies is operational control:

- Switch off transformers when tools are not in use

- Use timers or smart distribution boards

- Avoid leaving temporary site electrics energised overnight

Idle loss reduction delivers immediate energy savings.

5. Maintain and Inspect Regularly

Poor connections, damaged insulation, and overheating all increase transformer energy losses.

Routine maintenance should include:

- Visual inspections

- Thermal checks

- Load balancing

- Ventilation clearance checks

Well-maintained transformers operate more efficiently and safely.

Safety and Efficiency Go Hand in Hand

Safety and efficiency are not opposing goals. In fact, well-designed systems deliver both. If you want a deeper explanation of the safety rationale behind 110V systems, see our related article:

“Why Construction Sites Use 110V: Safety, Standards & Smarter Power”.

It explains how voltage reduction, isolation, and smarter power distribution improve both worker protection and energy performance on modern sites.

Standard vs Energy Efficient 110V Transformers

| Feature | Standard 110V Site Transformer | Energy Efficient / Low Loss Transformer |

| Core material | Conventional steel | High-grade silicon or amorphous steel |

| No-load losses | Higher | Significantly reduced |

| Load efficiency | Moderate | High |

| Heat generation | Higher | Lower |

| Energy consumption | Higher over time | Reduced operating costs |

| Suitable for temporary site electrics | Yes | Yes (recommended) |

| Sustainability impact | Moderate | Lower carbon footprint |

FAQs

Are 110V site transformers energy efficient?

They can be. Energy efficient transformers specifically designed for 110V applications offer much lower losses than older or basic models.

Do low loss transformers cost more?

Initial cost is slightly higher, but energy saving transformers typically pay for themselves through reduced electricity bills and longer lifespan.

Can I improve efficiency without replacing my transformer?

Yes. Reducing idle time, improving maintenance, and right-sizing loads can significantly cut transformer energy losses.

Are energy efficient transformers safer?

Yes. Lower heat output and improved insulation enhance reliability, reducing the risk of failure while maintaining safety standards.