Daily Inspection of Electrical Tools and Equipment at Construction Sites

Daily inspection of electrical tools and equipment is essential for preventing accidents and maintaining safe power distribution on UK construction sites. Consistent visual checks help reduce electrical faults, downtime, and serious safety incidents.

Construction Site Electrical Safety: Why Daily Inspections Are Essential

Construction sites depend on temporary electrical systems in harsh conditions. Dust, moisture, vibration, and damage make equipment vulnerable. Daily inspections reduce construction electrical hazards and improve construction site electrical safety by identifying risks early.

Electrical Tools Inspection Checklist

A clear electrical tools inspection checklist should be completed at the start of every shift.

Plugs and Connectors

- No cracks, burns, or loose pins

- Correct voltage plug fitted (yellow 110V or blue 240V)

- Cable grip secure with no exposed inner cores

Cables and Extension Leads

- No cuts, abrasions, or taped repairs

- Correct cable size for the application (1.5mm² or 2.5mm²)

- Outer insulation intact along the full length

Electrical Tools

- Tool casing undamaged and secure

- Switches operating correctly

- No signs of overheating, sparking, or abnormal noise

Power Distribution Equipment

- Cable reels fully unwound when in use

- Sockets not overloaded

- Equipment positioned on stable, dry surfaces

Electrical Tools Safety Checklist for UK Construction Sites

| Safety Check | Description |

| Use of 110V tools | Ensure 110V tools are used wherever reasonably practicable to reduce shock risk. |

| PAT testing | Check that PAT testing labels are present and in date for all electrical tools. |

| RCD protection | Confirm that RCD protection is provided where required for added safety. |

| Removal of damaged tools | Immediately remove any damaged or faulty tools from service to prevent accidents. |

| Trained operatives only | Ensure only trained personnel operate electrical equipment on site. |

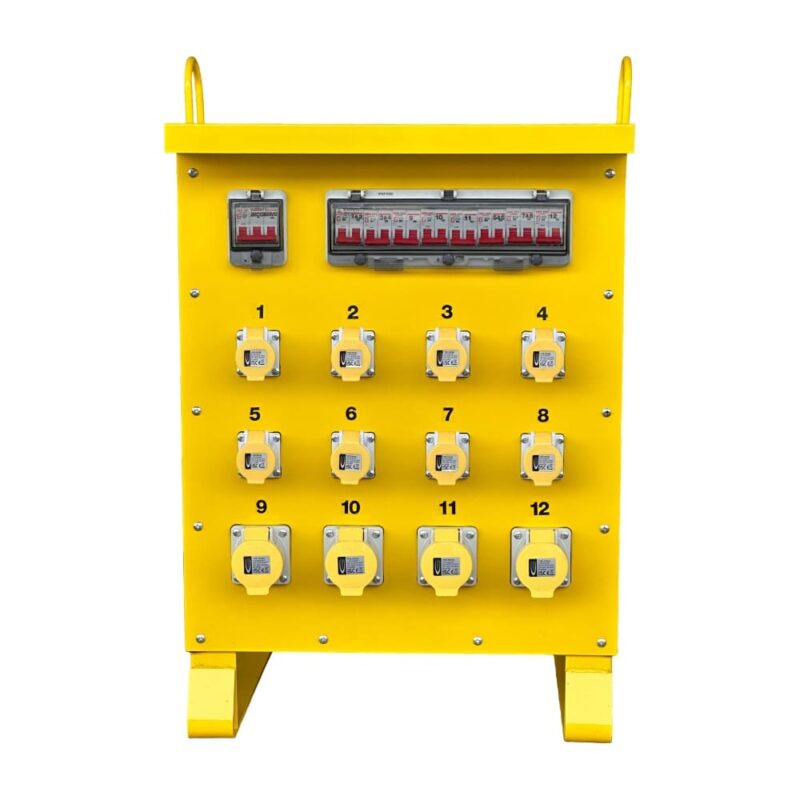

Site Transformers and Safe Temporary Power Distribution

Site transformers are fundamental to safe power management on UK construction sites, reducing voltage and limiting the severity of electric shock.

Common site-ready options include:

- 20kVA Site Transformer 110V Three Phase – suitable for large sites running multiple tools

- 110V Site Transformer 3.3kVA – Intermittent Rated 3300VA – ideal for smaller or mobile setups

Daily inspection of transformers should include:

- No visible damage to casing or sockets

- Correct load distribution

- Adequate ventilation and secure placement

This approach aligns with best practices outlined in Site Transformers: How to Ensure Power Safety on UK Construction Sites.

Cable Reels and Electrical Cable Management on Construction Sites

Proper use of cable reels supports effective electrical cable management in construction site environments and helps prevent overheating and voltage drop.

Typical site-rated solutions include:

- 110V Cable Reel 50m 1.5mm 16amp Plug and 2x16amp Socket

- 110V Cable Drum 100m 2.5mm 3 Core Yellow Cable – (10902)

Daily checks should ensure:

- Reels are fully unwound during use

- No cable deformation, heat damage, or exposed conductors

- Current ratings match connected equipment

For further guidance, contractors often reference Cable Reels 110V & 240V: Complete Safety and Selection Guide for UK Sites.

Extension Leads: A High-Risk Item Requiring Daily Inspection

Extension leads are among the most commonly damaged items on site and require careful daily inspection.

Frequently used site options include:

- 240V Extension Lead 14m 1.5mm Cable 16amp for controlled environments

- 110V Extension Lead 25m 2.5mm Cable 32amp for heavy-duty tools

Inspection should focus on:

- Full-length cable integrity

- Secure plugs and sockets

- Safe routing to avoid trip, crush, and water hazards

More detailed selection and usage guidance can be found in Extension Leads for Site Use: Complete Guide to Powering UK Construction Projects.

Electrical Cable Management in Construction Site Environments

Good electrical cable management in construction site operations improves safety and efficiency:

- Route cables away from walkways where possible

- Use cable ramps, hooks, or overhead routing

- Avoid sharp bends and excessive tension

- Keep cables clear of water, heat, and moving plant

Daily inspections should confirm that cable routing remains safe as site conditions change.

Record Keeping and Site Responsibility

To maintain consistent standards:

- Record daily inspection findings

- Clearly tag and isolate faulty equipment

- Ensure supervisors review checks regularly

- Reinforce safe practices through toolbox talks

This ensures electrical safety remains a routine part of site operations rather than a reactive measure.

FAQs

Are daily electrical inspections required on UK construction sites?

Daily visual checks are strongly recommended under UK health and safety guidance due to the high-risk nature of construction environments.

Why is 110V power preferred on construction sites?

110V centre-tapped systems significantly reduce the risk of serious electric shock compared to 240V supplies.

Should cable reels always be fully unwound?

Yes. Using a coiled reel under load can cause overheating and increase fire risk.

Can damaged extension leads be temporarily repaired?

No. Temporary repairs are unsafe. Damaged leads must be removed from service immediately.

How do site transformers reduce electrical risk?

They step down voltage and isolate circuits, improving overall electrical safety on site.